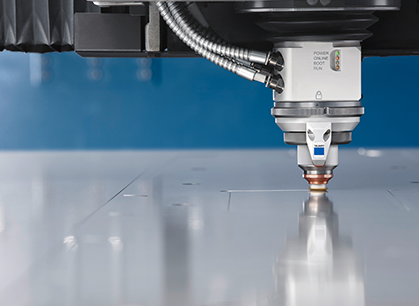

AQUA CUT

The Aqua Cut device we have is the only one of its kind in Poland and second in Europe. On a table with a length of nearly 14 m, a 4.5 m portal was installed, on which three cutting heads, numerically controlled, were placed.

Two heads are used for cutting under a water jet

pressure close to 4150 atm in 2D and 3D. This huge pressure is generated by a pump manufactured by KMT – the global leader – Streamline SLV-50 HP PLUS.

When using two cutting heads with water, we cut out all shapes in both 2D and 3D with a thickness of up to 200 mm,

in materials such as: steel (all types of steel sheets including tool steel), plastics, glass, stones

The advantages of waterjet cutting:

- very high accuracy even with materials of considerable thickness,

- perfect cutting edge,

- the possibility of combining different materials to obtain the original visual and useful effect,

- lack of thermal stresses and discoloration of the material formed under the influence of high temperature during laser cutting,

- no local hardening of the material,

- the possibility of cutting hardened materials without the risk of local hardening.